- Home

- Cable Cleats for Electrical Installations

- Technical

- Twin arc profiles

- Certificate Downloads

- Cable Cleat Accessories

- Cable Cleat Nut Spacer

- Cable Cleat Selection

- Cable Formations

- Recommended Cleat Spacings

- Catalogue Downloads

- Cleat Fixing Packs

- Fire Performance

- Galvanic Corrosion

- Good Installation Practices

- How To Order

- Intermediate Restraints

- Materials

- Product Downloads

- Product Overview

- Resistance Classifications

- Twin arc profiles

- What is a Cable Cleat?

- What is a Short Circuit?

- Why use a Cable Cleat?

Need more help? Contact our team on +44 191 265 7411

Twin arc profiles

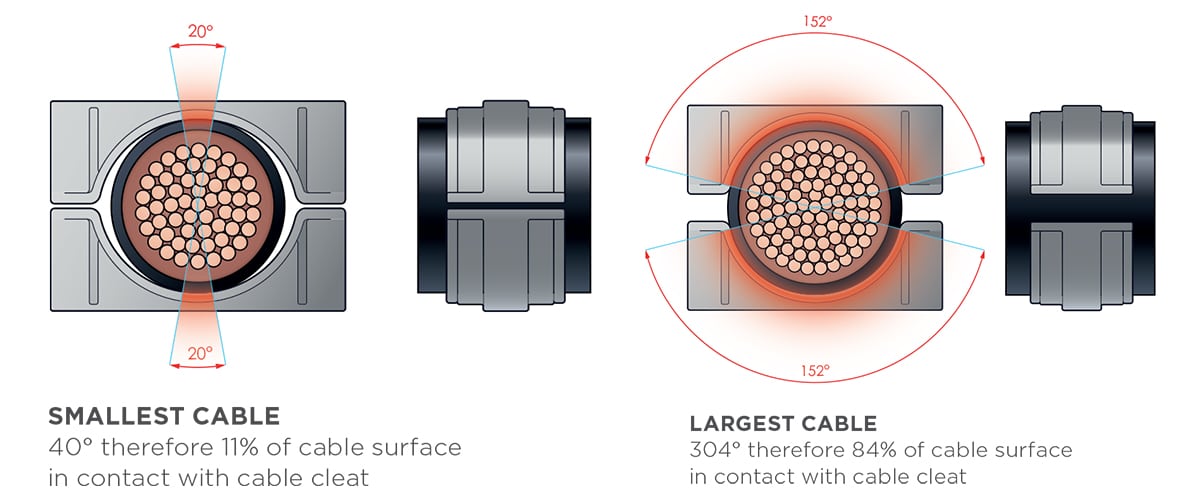

Disadvantages of standard cable cleat profiles

In the past many cable cleats had a simple circular internal profile; this gives excellent surface contact on the maximum size of cable in the clamping range (84% of the cable in contact with the cable cleat) which in turn gives an excellent level of axial restraint.

However, on the minimum size of cable in the clamping range, little more than a point contact between the top and bottom of the cable and the cable cleat (11% of the cable in contact with the cable cleat) is achieved which gives a very poor level of axial restraint.

Due to the poor surface contact (only in the centres at the top and bottom of the cable) on the smaller sizes of cable in the range, it is easy to over-tighten the fixing bolts. This not only crushes the cable out of shape, it also deforms the cable cleat around the cable therefore stressing the cable cleat material. It is not possible to have the same bolt torque settings for every size of cable, since the smaller cables allow the cable cleat to deform (closing the gaps either side of the cable to cable cleat contact areas in the centre) and the torque level will be reached later, so installation procedures can be ambiguous.

Typical range taking capabilities of prior art cable cleats vary from 5-8mm on cable outside diameter.

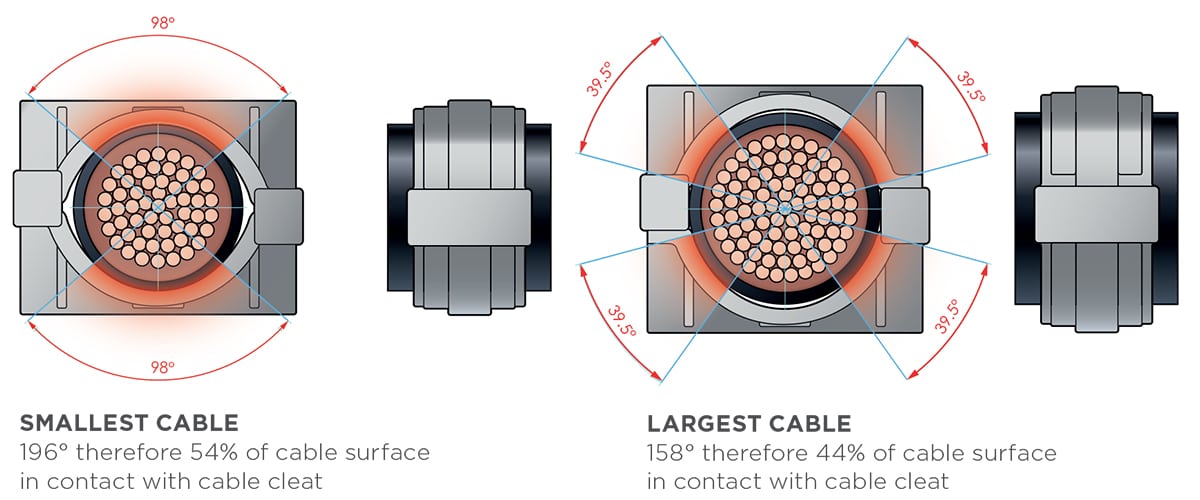

Benefits of CMP Twin Arc Cable Cleat Profiles

Analysing CMP’s single bolt Sabre, Valiant and Solace and two bolt Falcon, Zenith and Themis cable cleat internal profile, there are two separate arcs joined tangentially; one arc suited to the minimum sized cable and the other arc suited to the maximum sized cable in the clamping range. The tangential join means that all cable sizes

in-between are clamped just as effectively.

This gives an almost uniform level of surface contact throughout the clamping range (44% on the minimum and 54% on the maximum sized cables) meaning axial restraint is just as good on the smaller sizes of cable in the range as it is for the largest.

The better comparative surface area contact throughout the clamping range also means that the same torque settings can be used, no matter what size of cable is fitted; removing any uncertainty during installation.

By using the new twin arc design, CMP has also dramatically increased the range taking capability of these types of cable cleat, which varies from 10-15mm on cable outside diameter.