- Home

- Cable Glands

- Products

- Industrial / General Purpose

- E1U | Industrial Cable Gland

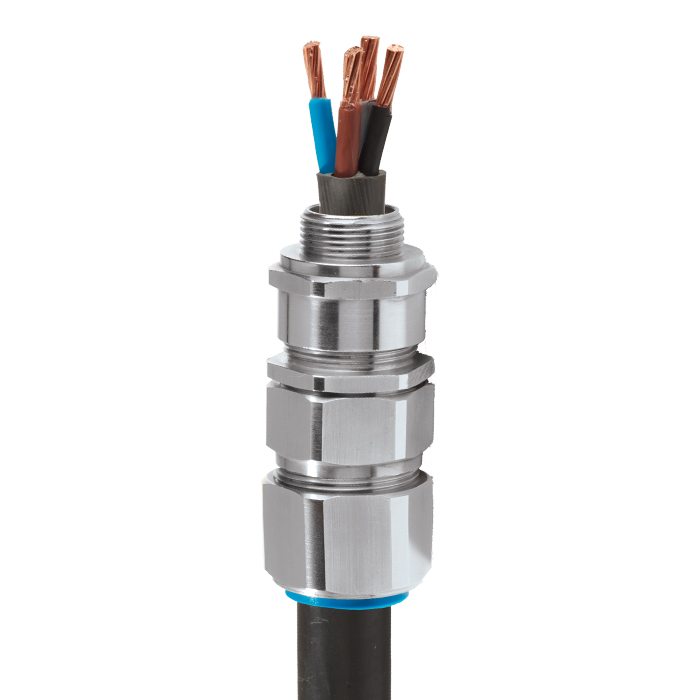

E1U | Industrial Cable Gland For all types of Armoured Cables

We'd like to keep in touch

We have some exciting things in the pipeline - if you'd like to be the first to know please enter your email address below.

Double Seal Industrial Cable Gland

• Metal-to-metal armour clamping

• Direct & remote installation

• Permanently crimped, low impedance earth termination

• Secure against self-loosening

• Displacement type inner seal

• Controlled outer ‘load retention’ seal

• Unique OSTG prevents overtightening

• Designed to prevent Coldflow

• Deluge protection option

• -60°C to +130°C (standard), -20°C to 200°C (ThermIn option available)

• EMC tested

For under / oversized armour wires click here

| Design Specification | BS 6121:Part 1:1989, IEC 62444, EN 62444 |

| Mechanical Classifications * | Impact = Level 8, Retention = Class D |

| Enclosure Protection | IK10 to IEC 62262 (20 joules) Brass & Stainless Steel only |

| Electrical Classifications * | Category B (Category A when used with braid, tape or pliable wire armour cables) |

| GOST R Certificate | POCC.GB.HA46.H00140 |

| Marine Approvals | LRS: 01/00171 , ABS: 16-LD1472056-PDA |

| Ingress Protection Rating ** | IP66 as standard (IP67, IP68 available upon request) |

| Cable Gland Material | Brass, Electroless Nickel Plated Brass, Aluminium |

| Seal Material | CMP Thermoset Rubber |

| Cable Type | Single Wire Armour (SWA), Aluminium Wire Armour (AWA), Pliable Wire Armour (PWA), Steel Tape Armour (STA), Wire Braid Armour, Aluminium Strip Armour (ASA), Screened Flexible (EMC) Wire Braid (e.g. CY / SY), Armoured & Jacketed |

| Armour Clamping | Reversible Armour Cone & AnyWay Universal Clamping Ring |

| Sealing Technique | CMP Inner Displacement Seal & Unique CMP ‘LRS’ TM Outer Load Retention Seal |

| Sealing Area(s) | Cable Inner Bedding & Outer Cable Sheath |

| Optional Accessories | Locknuts, Earth Tags, Serrated Washers, Entry Thread Seals, Shrouds,Ingress Discs |

| Optional Installation Tools | Spanners, Armour Former Tool |

Note : * Mechanical & Electrical Classifications applied as per IEC 62444 & EN 6244

** Refer to Maintaining a Seal for further information on Ingress Protection Ratings

Certificates

Product Selection Table

Click here to view how to order

| Cable Gland Size | Available Entry Threads 'C' (Alternate Metric Thread Lengths Available) | Cable Bedding Diameter 'A' | Overall Cable Diameter 'B' | Armour Range | Across Flats 'D' | Across Corners 'D' | Protrusion Length 'F' | Combined Ordering Reference (*Brass Metric) | Shroud | Cable Gland Weight (Ozs) |

|||||||||||

| Standard | Option | Grooved Cone (X) | Stepped Cone (W) | ||||||||||||||||||

| Metric | Thread Length (Metric) 'E' | NPT | Thread Length (NPT) 'E' | NPT | Min | Max | Min | Max | Min | Max | Min | Max | Max | Max | Size | Type | Ordering Suffix |

||||

| 20s16 | M20 | 0.39 | 1/2' | 0.78 | 3/4' | 0.12 | 0.34 | 0.24 | 0.52 | 0.01 | 0.04 | 0.03 | 0.05 | 0.94 | 1.04 | 2.85 | 20S16 | E1U | 1RA | PVC04 | 5.75 |

| 20S | M20 | 0.39 | 1/2' | 0.78 | 3/4' | 0.24 | 0.46 | 0.37 | 0.63 | 0.01 | 0.04 | 0.03 | 0.05 | 0.94 | 1.04 | 2.76 | 20S | E1U | 1RA | PVC04 | 5.29 |

| 20 | M20 | 0.39 | 1/2' | 0.78 | 3/4' | 0.26 | 0.55 | 0.49 | 0.82 | 0.02 | 0.04 | 0.03 | 0.05 | 1.20 | 1.32 | 2.87 | 20 | E1U | 1RA | PVC06 | 7.41 |

| 25S | M25 | 0.39 | 3/4' | 0.8 | 1' | 0.44 | 0.78 | 0.55 | 0.87 | 0.02 | 0.05 | 0.05 | 0.06 | 1.48 | 1.63 | 3.50 | 25S | E1U | 1RA | PVC09 | 11.64 |

| 25 | M25 | 0.39 | 3/4' | 0.8 | 1' | 0.44 | 0.78 | 0.72 | 1.03 | 0.02 | 0.05 | 0.05 | 0.06 | 1.48 | 1.63 | 3.50 | 25 | E1U | 1RA | PVC09 | 11.64 |

| 32 | M32 | 0.39 | 1' | 0.98 | 1 1/4' | 0.67 | 1.03 | 0.93 | 1.33 | 0.02 | 0.05 | 0.06 | 0.08 | 1.81 | 1.99 | 3.39 | 32 | E1U | 1RA | PVC11 | 15.17 |

| 40 | M40 | 0.59 | 1 1/4' | 1.01 | 1 1/2' | 0.87 | 1.26 | 1.10 | 1.59 | 0.02 | 0.06 | 0.06 | 0.08 | 2.17 | 2.38 | 3.54 | 40 | E1U | 1RA | PVC15 | 21.87 |

| 50S | M50 | 0.59 | 1 1/2' | 1.03 | 2' | 1.16 | 1.50 | 1.39 | 1.84 | 0.02 | 0.06 | 0.08 | 0.10 | 2.36 | 2.60 | 3.58 | 50S | E1U | 1RA | PVC18 | 26.46 |

| 50 | M50 | 0.59 | 2' | 1.06 | 2 1/2' | 1.40 | 1.73 | 1.59 | 2.09 | 0.02 | 0.06 | 0.08 | 0.10 | 2.76 | 3.04 | 3.74 | 50 | E1U | 1RA | PVC21 | 33.51 |

| 63S | M63 | 0.59 | 2' | 1.06 | 2 1/2' | 1.58 | 1.96 | 1.8 | 2.34 | 0.02 | 0.06 | 0.08 | 0.10 | 2.95 | 3.25 | 4.02 | 63S | E1U | 1RA | PVC23 | 47.27 |

| 63 | M63 | 0.59 | 2 1/2' | 1.57 | 3' | 1.86 | 2.20 | 2.15 | 2.59 | 0.02 | 0.06 | 0.08 | 0.10 | 3.15 | 3.46 | 4.09 | 63 | E1U | 1RA | PVC25 | 47.27 |

| 75S | M75 | 0.59 | 2 1/2' | 1.57 | 3' | 2.08 | 2.44 | 2.32 | 2.83 | 0.02 | 0.06 | 0.08 | 0.10 | 3.54 | 3.90 | 4.53 | 75S | E1U | 1RA | PVC28 | 74.43 |

| 75 | M75 | 0.59 | 3' | 1.63 | 3 1/2' | 2.33 | 2.67 | 2.63 | 3.09 | 0.02 | 0.06 | 0.1 | 0.12 | 3.94 | 4.33 | 4.61 | 75 | E1U | 1RA | PVC30 | 85.36 |

| 90 | M90 | 0.94 | 3 1/2' | 1.69 | 4' | 2.62 | 3.09 | 3.00 | 3.56 | 0.03 | 0.06 | 0.12 | 0.16 | 4.50 | 4.94 | 5.79 | 90 | E1U | 1RA | PVC32 | 148.5 |

| 100 | M100 | 0.94 | 4' | 1.73 | 5' | 2.99 | 3.58 | 3.39 | 3.99 | 0.03 | 0.06 | 0.12 | 0.16 | 4.84 | 5.33 | 5.51 | 100 | E1U | 1RA | LSF33 | 156.97 |

| 115 | M115 | 0.94 | 4' | 1.73 | 5' | 3.39 | 3.85 | 4.00 | 4.34 | 0.03 | 0.06 | 0.12 | 0.16 | 5.25 | 5.78 | 6.38 | 115 | E1U | 1RA | LSF34 | 218.35 |

| 130 | M130 | 0.94 | 5' | 1.84 | 6' | 3.82 | 4.52 | 4.34 | 4.85 | 0.03 | 0.06 | 0.12 | 0.16 | 6.00 | 6.60 | 6.85 | 130 | E1U | 1RA | LSF35 | 294.19 |

| Dimensions displayed in inches unless otherwise stated | |||||||||||||||||||||

| Cable Gland Size | Available Entry Threads 'C' (Alternate Metric Thread Lengths Available) | Cable Bedding Diameter 'A' | Overall Cable Diameter 'B' | Armour Range | Across Flats 'D' | Across Corners 'D' | Protrusion Length 'F' | Combined Ordering Reference (*Brass Metric) | Shroud | Cable Gland Weight (Kgs) |

|||||||||||

| Standard | Option | Grooved Cone (X) | Stepped Cone (W) | ||||||||||||||||||

| Metric | Thread Length (Metric) 'E' | NPT | Thread Length (NPT) 'E' | NPT | Min | Max | Min | Max | Min | Max | Min | Max | Max | Max | Size | Type | Ordering Suffix |

||||

| 20s16 | M20 | 10.0 | 1/2' | 19.9 | 3/4' | 3.1 | 8.6 | 6.1 | 13.1 | 0.3 | 1.0 | 0.8 | 1.25 | 24.0 | 26.4 | 72.5 | 20S16 | E1U | 1RA | PVC04 | 0.16 |

| 20S | M20 | 10.0 | 1/2' | 19.9 | 3/4' | 6.1 | 11.6 | 9.5 | 15.9 | 0.3 | 1.0 | 0.8 | 1.25 | 24.0 | 26.4 | 70.0 | 20S | E1U | 1RA | PVC04 | 0.15 |

| 20 | M20 | 10.0 | 1/2' | 19.9 | 3/4' | 6.5 | 13.9 | 12.5 | 20.9 | 0.4 | 1.0 | 0.8 | 1.25 | 30.5 | 33.6 | 73.0 | 20 | E1U | 1RA | PVC06 | 0.21 |

| 25S | M25 | 10.0 | 3/4' | 20.2 | 1' | 11.1 | 19.9 | 14 | 22 | 0.4 | 1.2 | 1.25 | 1.6 | 37.5 | 41.3 | 89.0 | 25S | E1U | 1RA | PVC09 | 0.33 |

| 25 | M25 | 10.0 | 3/4' | 20.2 | 1' | 11.1 | 19.9 | 18.2 | 26.2 | 0.4 | 1.2 | 1.25 | 1.6 | 37.5 | 41.3 | 89.0 | 25 | E1U | 1RA | PVC09 | 0.33 |

| 32 | M32 | 10.0 | 1' | 25.0 | 1 1/4' | 17.0 | 26.2 | 23.7 | 33.9 | 0.4 | 1.2 | 1.6 | 2.0 | 46.0 | 50.6 | 86.0 | 32 | E1U | 1RA | PVC11 | 0.43 |

| 40 | M40 | 15.0 | 1 1/4' | 25.6 | 1 1/2' | 22.0 | 32.1 | 27.9 | 40.4 | 0.4 | 1.6 | 1.6 | 2.0 | 55.0 | 60.5 | 90.0 | 40 | E1U | 1RA | PVC15 | 0.62 |

| 50S | M50 | 15.0 | 1 1/2' | 26.1 | 2' | 29.5 | 38.1 | 35.2 | 46.7 | 0.4 | 1.6 | 2.0 | 2.5 | 60.0 | 66.0 | 91.0 | 50S | E1U | 1RA | PVC18 | 0.75 |

| 50 | M50 | 15.0 | 2' | 26.9 | 2 1/2' | 35.6 | 44.0 | 40.4 | 53 | 0.6 | 1.6 | 2.0 | 2.5 | 70.1 | 77.1 | 95.0 | 50 | E1U | 1RA | PVC21 | 0.95 |

| 63S | M63 | 15.0 | 2' | 26.9 | 2 1/2' | 40.1 | 49.9 | 45.6 | 59.4 | 0.6 | 1.6 | 2.0 | 2.5 | 75.0 | 82.5 | 102.0 | 63S | E1U | 1RA | PVC23 | 1.34 |

| 63 | M63 | 15.0 | 2 1/2' | 39.9 | 3' | 47.2 | 55.9 | 54.6 | 65.8 | 0.6 | 1.6 | 2.0 | 2.5 | 80.0 | 88.0 | 104.0 | 63 | E1U | 1RA | PVC25 | 1.34 |

| 75S | M75 | 15.0 | 2 1/2' | 39.9 | 3' | 52.8 | 61.9 | 59.0 | 72.0 | 0.6 | 1.6 | 2.0 | 2.5 | 90.0 | 99.0 | 115.0 | 75S | E1U | 1RA | PVC28 | 2.11 |

| 75 | M75 | 15.0 | 3' | 41.5 | 3 1/2' | 59.1 | 67.9 | 66.7 | 78.4 | 0.6 | 1.6 | 2.5 | 3.0 | 100.0 | 110 | 117.0 | 75 | E1U | 1RA | PVC30 | 2.42 |

| 90 | M90 | 24.0 | 3 1/2' | 42.8 | 4' | 66.6 | 78.6 | 76.2 | 90.3 | 0.8 | 1.6 | 3.15 | 4.0 | 114.3 | 125.4 | 147.0 | 90 | E1U | 1RA | PVC32 | 4.21 |

| 100 | M100 | 24.0 | 4' | 44.0 | 5' | 76.0 | 90.9 | 86.1 | 101.4 | 0.8 | 1.6 | 3.15 | 4.0 | 123.0 | 135.3 | 140.0 | 100 | E1U | 1RA | LSF33 | 4.45 |

| 115 | M115 | 24.0 | 4' | 44.0 | 5' | 86.0 | 97.9 | 101.5 | 110.2 | 0.8 | 1.6 | 3.15 | 4.0 | 133.4 | 146.7 | 162.0 | 115 | E1U | 1RA | LSF34 | 6.19 |

| 130 | M130 | 24.0 | 5' | 46.8 | 6' | 97.0 | 114.9 | 110.2 | 123.2 | 0.8 | 1.6 | 3.15 | 4.0 | 152.4 | 167.6 | 174.0 | 130 | E1U | 1RA | LSF35 | 8.34 |

| Dimensions displayed in millimeters unless otherwise stated | |||||||||||||||||||||

Cable Gland & Enclosure Material Selection ‘Quick Guide’

The specific conditions of any installation will play a major part in the selection of the cable gland material, taking into account the level of environmental exposure along with the nature of the enclosure and cable armour or braid material.

Read moreCombating Galvanic Corrosion at CMP

The type and thickness of nickel coatings applied to brass cable glands varies significantly around the world, and many of the solutions adopted are inherently porous, meaning that they are unable to provide complete protection against chemical attack, corrosion, or material break-down. There are typically two types of nickel plating in common use, these being electro nickel plating and electro-less nickel plating.

Read moreMaterial Selection & Preservation for Longevity of Service

The selection of material by a customer often comes down to either carefully developed client specifications; cost / value options; or a combination of both. There will be numerous applications where the material selection is a lot more critical than it is in others.

Read moreVisit our Knowledge Base for technical expertise and advice, gathered over CMP's 60+ years' experience in the art of terminating cable glands.

Sign up now