- Home

- Cable Glands

- Products

- Industrial / General Purpose

- E1W | Industrial Cable Gland

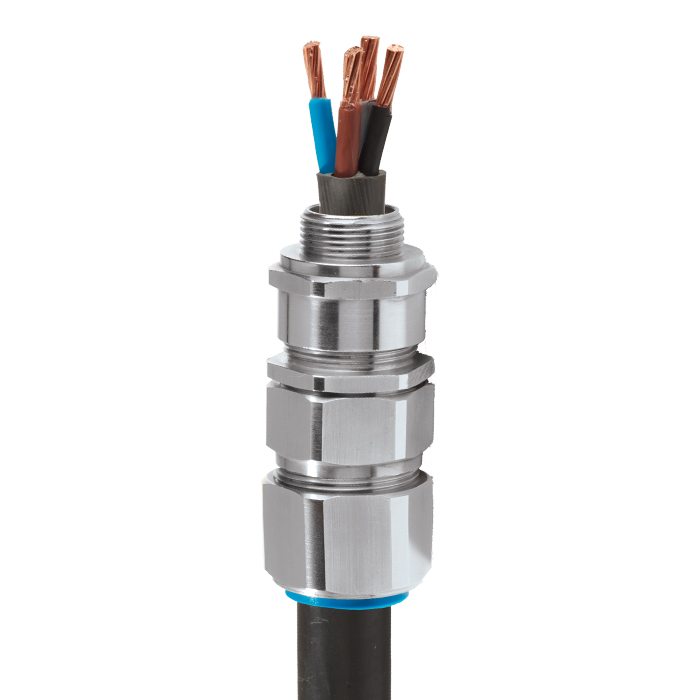

E1W | Industrial Cable Gland For all types of Steel & Aluminium Wire Armoured Cables

We'd like to keep in touch

We have some exciting things in the pipeline - if you'd like to be the first to know please enter your email address below.

E1W Double Seal Industrial Cable Gland

• Metal-to-metal armour clamping

• Direct & remote installation

• Permanently crimped, low impedance earth termination

• Secure against self-loosening

• Displacement type inner seal

• Controlled outer ‘load retention’ seal

• Unique OSTG prevents overtightening

• Designed to prevent Coldflow

• Deluge protection option

• -60°C to +130°C

• Superior EMC performance

For under / oversized armour wires click here

| Design Specification | BS 6121:Part 1:1989, IEC 62444, EN 62444 |

| Mechanical Classifications * | Impact = Level 8, Retention = Class D |

| Enclosure Protection | IK10 to IEC 62262 (20 joules) Brass & Stainless Steel only |

| Electrical Classifications * | Category B |

| GOST R Certificate | POCC.GB.HA46.H00140 |

| Marine Approvals | LRS: 01/00171 , ABS: 16-LD1472056-PDA |

| Ingress Protection Rating ** | IP66 as standard (IP67, IP68 available upon request) |

| Cable Gland Material | Brass, Electroless Nickel Plated Brass, Aluminium |

| Seal Material | CMP Thermoset Rubber |

| Cable Type | Single Wire Armour (SWA), Aluminium Wire Armour (AWA) |

| Armour Clamping | Detachable Armour Cone & AnyWay Universal Clamping Ring |

| Sealing Technique | CMP Inner Displacement Seal & Unique CMP ‘LRS’ TM Outer Load Retention Seal |

| Sealing Area(s) | Cable Inner Bedding & Outer Cable Sheath |

| Optional Accessories | Locknuts, Earth Tags, Serrated Washers, Entry Thread Seals, Shrouds,Ingress Discs |

| Optional Installation Tools | Spanners, Armour Former Tool |

Note : * Mechanical & Electrical Classifications applied as per IEC 62444 & EN 62444

** Refer to Maintaining a Seal for further information on Ingress Protection Ratings

Certificates

Product Selection Table

Click here to view how to order

| Cable Gland Size | Available Entry Threads 'C' (Alternate Metric Thread Lengths Available) | Cable Bedding Diameter 'A' | Overall Cable Diameter 'B' | Armour Range | Across Flats 'D' | Across Corners 'D' | Protrusion Length 'F' | Combined Ordering Reference (*Brass Metric) | Shroud | Cable Gland Weight (Ozs) |

|||||||||

| Standard | Option | ||||||||||||||||||

| Metric | Thread Length (Metric) 'E' | NPT | Thread Length (NPT) 'E' | NPT | Min | Max | Min | Max | Min | Max | Max | Max | Size | E1W | Ordering Suffix |

||||

| 20s16 | M20 | 0.39 | 1/2' | 0.78 | 3/4' | 0.12 | 0.34 | 0.24 | 0.52 | 0.03 | 0.05 | 0.94 | 1.04 | 2.85 | 20S16 | E1W | 1RA | PVC04 | 5.75 |

| 20S | M20 | 0.39 | 1/2' | 0.78 | 3/4' | 0.24 | 0.46 | 0.37 | 0.63 | 0.03 | 0.05 | 0.94 | 1.04 | 2.76 | 20S | E1W | 1RA | PVC04 | 5.29 |

| 20 | M20 | 0.39 | 1/2' | 0.78 | 3/4' | 0.26 | 0.55 | 0.49 | 0.82 | 0.03 | 0.05 | 1.20 | 1.32 | 2.87 | 20 | E1W | 1RA | PVC06 | 7.41 |

| 25S | M25 | 0.39 | 3/4' | 0.8 | 1' | 0.44 | 0.78 | 0.55 | 0.87 | 0.05 | 0.06 | 1.48 | 1.63 | 3.50 | 25S | E1W | 1RA | PVC09 | 11.64 |

| 25 | M25 | 0.39 | 3/4' | 0.8 | 1' | 0.44 | 0.78 | 0.72 | 1.03 | 0.05 | 0.06 | 1.48 | 1.63 | 3.50 | 25 | E1W | 1RA | PVC09 | 11.64 |

| 32 | M32 | 0.39 | 1' | 0.98 | 1 1/4' | 0.67 | 1.03 | 0.93 | 1.33 | 0.06 | 0.08 | 1.81 | 1.99 | 3.39 | 32 | E1W | 1RA | PVC11 | 15.17 |

| 40 | M40 | 0.59 | 1 1/4' | 1.01 | 1 1/2' | 0.87 | 1.26 | 1.10 | 1.59 | 0.06 | 0.08 | 2.17 | 2.38 | 3.54 | 40 | E1W | 1RA | PVC15 | 21.87 |

| 50S | M50 | 0.59 | 1 1/2' | 1.03 | 2' | 1.16 | 1.5 | 1.39 | 1.84 | 0.08 | 0.10 | 2.36 | 2.60 | 3.58 | 50S | E1W | 1RA | PVC18 | 26.46 |

| 50 | M50 | 0.59 | 2' | 1.06 | 2 1/2' | 1.40 | 1.73 | 1.59 | 2.09 | 0.08 | 0.10 | 2.76 | 3.04 | 3.74 | 50 | E1W | 1RA | PVC21 | 33.51 |

| 63S | M63 | 0.59 | 2' | 1.06 | 2 1/2' | 1.58 | 1.96 | 1.8 | 2.34 | 0.08 | 0.10 | 2.95 | 3.25 | 4.02 | 63S | E1W | 1RA | PVC23 | 47.27 |

| 63 | M63 | 0.59 | 2 1/2' | 1.57 | 3' | 1.86 | 2.2 | 2.15 | 2.59 | 0.08 | 0.10 | 3.15 | 3.46 | 4.09 | 63 | E1W | 1RA | PVC25 | 47.27 |

| 75S | M75 | 0.59 | 2 1/2' | 1.57 | 3' | 2.08 | 2.44 | 2.32 | 2.83 | 0.08 | 0.10 | 3.54 | 3.90 | 4.53 | 75S | E1W | 1RA | PVC28 | 74.43 |

| 75 | M75 | 0.59 | 3' | 1.63 | 3 1/2' | 2.33 | 2.67 | 2.63 | 3.09 | 0.10 | 0.12 | 3.94 | 4.33 | 4.61 | 75 | E1W | 1RA | PVC30 | 85.36 |

| 90 | M90 | 0.94 | 3 1/2' | 1.69 | 4' | 2.62 | 3.09 | 3.00 | 3.56 | 0.12 | 0.16 | 4.50 | 4.94 | 5.79 | 90 | E1W | 1RA | PVC32 | 148.5 |

| 100 | M100 | 0.94 | 4' | 1.73 | 5' | 2.99 | 3.58 | 3.39 | 3.99 | 0.12 | 0.16 | 4.84 | 5.33 | 5.51 | 100 | E1W | 1RA | LSF33 | 156.97 |

| 115 | M115 | 0.94 | 4' | 1.73 | 5' | 3.39 | 3.85 | 4.00 | 4.34 | 0.12 | 0.16 | 5.25 | 5.78 | 6.38 | 115 | E1W | 1RA | LSF34 | 218.35 |

| 130 | M130 | 0.94 | 5' | 1.84 | 6' | 3.82 | 4.52 | 4.34 | 4.85 | 0.12 | 0.16 | 6.00 | 6.60 | 6.85 | 130 | E1W | 1RA | LSF35 | 294.19 |

| Dimensions displayed in inches unless otherwise stated | |||||||||||||||||||

| Cable Gland Size | Available Entry Threads 'C' (Alternate Metric Thread Lengths Available) | Cable Bedding Diameter 'A' | Overall Cable Diameter 'B' | Armour Range | Across Flats 'D' | Across Corners 'D' | Protrusion Length 'F' | Combined Ordering Reference (*Brass Metric) | Shroud | Cable Gland Weight (Kgs) |

|||||||||

| Standard | Option | ||||||||||||||||||

| Metric | Thread Length (Metric) 'E' | NPT | Thread Length (NPT) 'E' | NPT | Min | Max | Min | Max | Min | Max | Max | Max | Size | Type | Ordering Suffix |

||||

| 20s16 | M20 | 10.0 | 1/2" | 19.9 | 3/4" | 3.1 | 8.6 | 6.1 | 13.1 | 0.8 | 1.25 | 24.0 | 26.4 | 72.5 | 20S16 | E1W | 1RA | PVC04 | 0.16 |

| 20S | M20 | 10.0 | 1/2" | 19.9 | 3/4" | 6.1 | 11.6 | 9.5 | 15.9 | 0.8 | 1.25 | 24.0 | 26.4 | 70.0 | 20S | E1W | 1RA | PVC04 | 0.15 |

| 20 | M20 | 10.0 | 1/2" | 19.9 | 3/4" | 6.5 | 13.9 | 12.5 | 20.9 | 0.8 | 1.25 | 30.5 | 33.6 | 73.0 | 20 | E1W | 1RA | PVC06 | 0.21 |

| 25S | M25 | 10.0 | 3/4" | 20.2 | 1" | 11.1 | 19.9 | 14.0 | 22.0 | 1.25 | 1.6 | 37.5 | 41.3 | 89.0 | 25S | E1W | 1RA | PVC09 | 0.33 |

| 25 | M25 | 10.0 | 3/4" | 20.2 | 1" | 11.1 | 19.9 | 18.2 | 26.2 | 1.25 | 1.6 | 37.5 | 41.3 | 89.0 | 25 | E1W | 1RA | PVC09 | 0.33 |

| 32 | M32 | 10.0 | 1" | 25.0 | 1 1/4" | 17.0 | 26.2 | 23.7 | 33.9 | 1.6 | 2.0 | 46.0 | 50.6 | 86.0 | 32 | E1W | 1RA | PVC11 | 0.43 |

| 40 | M40 | 15.0 | 1 1/4" | 25.6 | 1 1/2" | 22.0 | 32.1 | 27.9 | 40.4 | 1.6 | 2.0 | 55.0 | 60.5 | 90.0 | 40 | E1W | 1RA | PVC15 | 0.62 |

| 50S | M50 | 15.0 | 1 1/2" | 26.1 | 2" | 29.5 | 38.1 | 35.2 | 46.7 | 2.0 | 2.5 | 60.0 | 66.0 | 91.0 | 50S | E1W | 1RA | PVC18 | 0.75 |

| 50 | M50 | 15.0 | 2" | 26.9 | 2 1/2" | 35.6 | 44.0 | 40.4 | 53.0 | 2.0 | 2.5 | 70.1 | 77.1 | 95.0 | 50 | E1W | 1RA | PVC21 | 0.95 |

| 63S | M63 | 15.0 | 2" | 26.9 | 2 1/2" | 40.1 | 49.9 | 45.6 | 59.4 | 2.0 | 2.5 | 75.0 | 82.5 | 102.0 | 63S | E1W | 1RA | PVC23 | 1.34 |

| 63 | M63 | 15.0 | 2 1/2" | 39.9 | 3" | 47.2 | 55.9 | 54.6 | 65.8 | 2.0 | 2.5 | 80.0 | 88.0 | 104.0 | 63 | E1W | 1RA | PVC25 | 1.34 |

| 75S | M75 | 15.0 | 2 1/2" | 39.9 | 3" | 52.8 | 61.9 | 59.0 | 72.0 | 2.0 | 2.5 | 90.0 | 99.0 | 115.0 | 75S | E1W | 1RA | PVC28 | 2.11 |

| 75 | M75 | 15.0 | 3" | 41.5 | 3 1/2" | 59.1 | 67.9 | 66.7 | 78.4 | 2.5 | 3.0 | 100.0 | 110.0 | 117.0 | 75 | E1W | 1RA | PVC30 | 2.42 |

| 90 | M90 | 24.0 | 3 1/2" | 42.8 | 4" | 66.6 | 78.6 | 76.2 | 90.3 | 3.15 | 4.0 | 114.3 | 125.4 | 147.0 | 90 | E1W | 1RA | PVC32 | 4.21 |

| 100 | M100 | 24.0 | 4" | 44.0 | 5" | 76.0 | 90.9 | 86.1 | 101.4 | 3.15 | 4.0 | 123.0 | 135.3 | 140.0 | 100 | E1W | 1RA | LSF33 | 4.45 |

| 115 | M115 | 24.0 | 4" | 44.0 | 5" | 86.0 | 97.9 | 101.5 | 110.2 | 3.15 | 4.0 | 133.4 | 146.7 | 162.0 | 115 | E1W | 1RA | LSF34 | 6.19 |

| 130 | M130 | 24.0 | 5" | 46.8 | 6" | 97.0 | 114.9 | 110.2 | 123.2 | 3.15 | 4.0 | 152.4 | 167.6 | 174.0 | 130 | E1W | 1RA | LSF35 | 8.34 |

| Dimensions displayed in millimeters unless otherwise stated | |||||||||||||||||||

Industry Standard Cable Gland Designations

Cable glands may be designed, tested and manufactured to various standards around the world, but as a long established UK-based manufacturer, part of CMP’s history includes close participation in the development of British Standards for these products.

Read moreBS 6121-1:1989 vs IEC 62444 / EN 62444

Whilst new standards such as IEC 62444 and EN 62444 have more recently been introduced, which CMP Products fully complies with, BS 6121-1:1989 still remains a very important benchmark for users and manufacturers around the world, due mainly to the fact that it is a more onerous construction standard than others published. This will therefore be especially relevant where a national cable gland standard isn’t available. The tables below show the maximum cable entry bore size and tolerances permitted through the range of BS 6121-1:1989 cable gland sizes.

Read moreCable Gland Sizing – Enlarged Cable Diameters

The CMP combination gland concept utilises the forward portion of one cable gland size andthe rear portion of the next cable gland size up (larger). This enables cable gland selection for braided or armoured cables where the difference between the inner bedding and outer sheath cannot be accommodated with a standard cable gland size. Combination cable glands for braided & armoured cables are available for both industrial and explosive atmospheres cable gland types with both inner and outer seals.

Read moreVisit our Knowledge Base for technical expertise and advice, gathered over CMP's 60+ years' experience in the art of terminating cable glands.

Sign up now